When it comes to plant dismantling and industrial demolition, the stakes are high. The processes involve not just tearing down structures but doing so in a manner that is safe, efficient, and environmentally responsible. It’s a complex field that requires expertise, precision, and a deep understanding of both the demolition process and the value of salvaged materials. In this context, Midwest Steel Company emerges as a leading service provider, offering an exemplary blend of demolition and surplus equipment dealing across the United States.

The Importance of Expertise in Demolition Projects

Demolition and dismantling projects are not merely about destruction. They are, in essence, about transformation and renewal. For industries ranging from petrochemical to power generation, the dismantling of outdated facilities is a necessary step towards modernization and environmental compliance. However, these projects demand a high level of expertise to ensure safety, regulatory compliance, and environmental protection. Midwest Steel Company, with over 55 years of experience, stands out as a beacon of expertise in this field.

The Midwest Steel Advantage

Midwest Steel Company offers a unique proposition as both a full-service demolition contractor and a surplus equipment dealer. This dual role enables them to provide outstanding performance on every project, coupled with lucrative equipment and scrap credits. Their approach ensures that clients not only benefit from their demolition services but also from an excellent return on investment through efficient salvaging.

The company’s capability in managing and recycling over 300 million pounds of scrap metal annually highlights their commitment to environmental stewardship. This aspect is particularly vital in today’s industrial landscape, where sustainability and resource conservation are paramount.

Services Tailored to Industry Needs

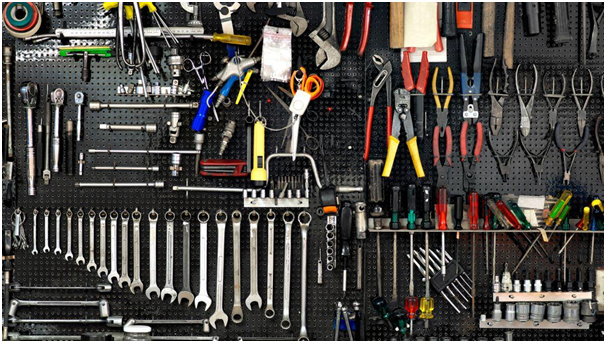

Midwest Steel’s range of services is comprehensive, catering to a wide array of industries and project requirements. From total demolition to selective and interior demolitions, their team is equipped to handle projects of any scale. Their expertise extends to dismantling and match-marking for relocation, showcasing their ability to support industries in transforming and upgrading their operations.

Their work with oil refineries, gas processing plants, pharmaceutical plants, and power generation plants, among others, demonstrates their versatility and commitment to serving the diverse needs of the industrial sector. This versatility is a testament to their deep understanding of the unique challenges and requirements across different industries.

Cost-Effective Solutions and Surplus Equipment

One of the standout features of Midwest Steel Company is their ability to offer cost-effective solutions for process equipment needs. By sourcing equipment directly from their dismantling job sites, they provide an opportunity for companies to achieve significant savings. This approach not only benefits their clients financially but also contributes to the broader goal of resource efficiency and sustainability.

The inventory of used and surplus process equipment that Midwest Steel offers is extensive, including everything from air fin heat exchangers to steam turbines. This inventory represents a valuable resource for industries looking to optimize their operations without the high costs associated with new equipment.

Conclusion

Choosing the right partner for plant dismantling and industrial demolition is crucial. Midwest Steel Company’s blend of expertise, innovation, and commitment to sustainability makes them a preferred choice for industries across the United States. Their comprehensive services, combined with the opportunity for significant cost savings through equipment salvage, set them apart in a competitive field.

For companies facing the complex challenges of dismantling and demolition, Midwest Steel offers not just services but solutions that are safe, efficient, and environmentally responsible. Their track record speaks to their ability to deliver on these promises, making them an invaluable partner in the industrial sector’s ongoing journey towards modernization and sustainability.